Performing powder handling operations in a confined environment such as a RABS is essential for enhancing safety during work phases. Although a RABS (Restricted Access Barrier System) cannot guarantee the... Read more

RABS Isolator

Performing powder handling operations in a confined environment such as a RABS is essential for enhancing safety during work phases.

Although a RABS (Restricted Access Barrier System) cannot guarantee the same safety standards as a rigid isolator, they can bring us surprisingly close to these standards.

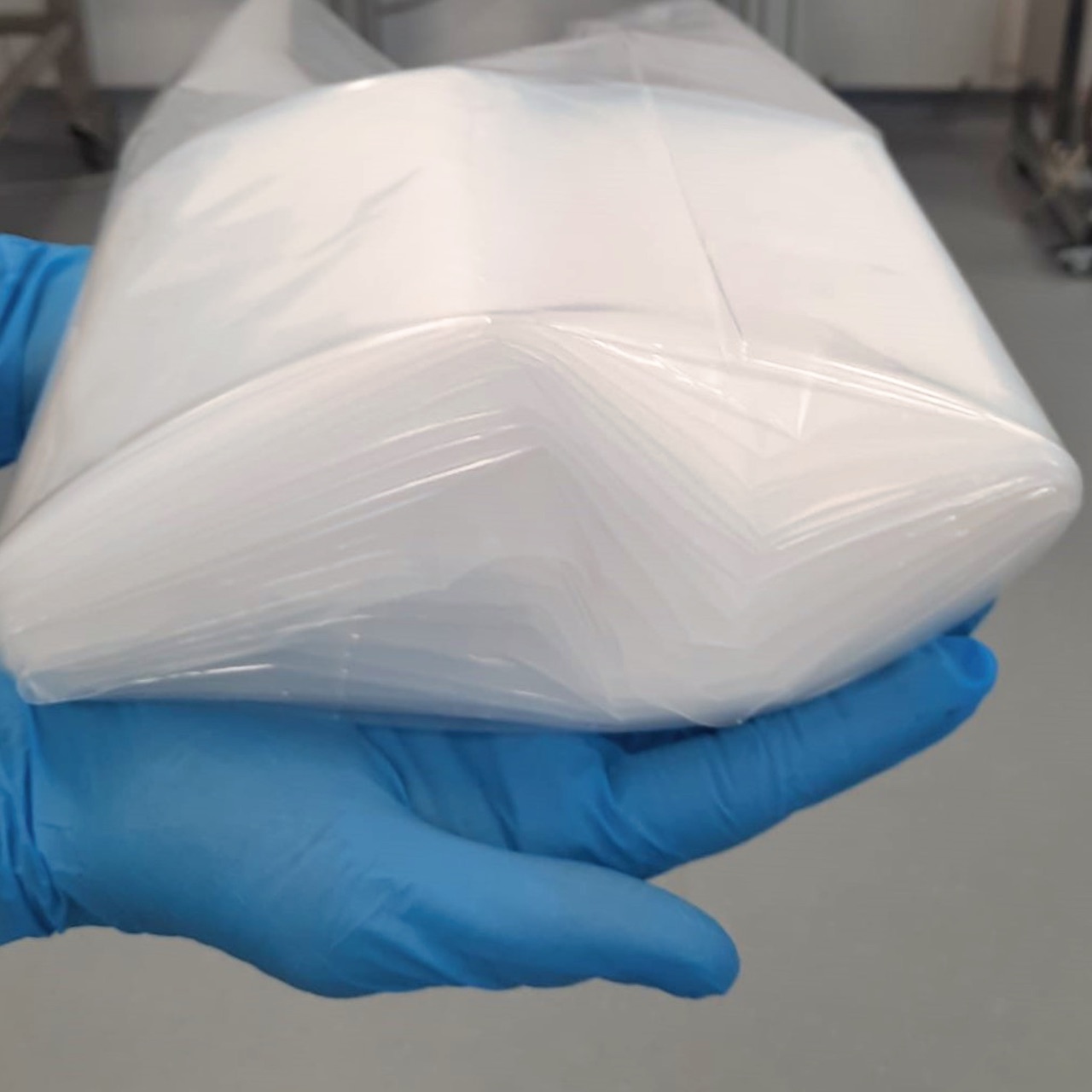

The chamber and post-chamber are separated by an internal door, and the insertion of a drum into the Restricted Access Barrier System is facilitated by an ergonomic linear sliding sled, mounted on a structure designed to support heavy loads. Once the drum is positioned, it’s simply a matter of fitting the wide sleeve which allows it to smoothly slide into the chamber through the dedicated canister, thus enabling easy material transfer.

From within the RABS, it is possible to perform dispensing operations in conditions that offer greater protection for both operators and the product itself, minimizing the risk of environmental contamination. The post-chamber allows for the safe transfer of samples outside, eliminating operator exposure to the product. The integrated Venturi system maintains a constant negative pressure flow, making this Restricted Access Barrier System a highly effective containment tool. This is a solution that offers an optimal balance between safety and investment, ideal for temporary situations or pilot projects, ensuring reduced delivery times and greater flexibility in case of modifications.

The main features of the RABS isolator are:

- GMP standard

- Steel frame

- Main Chamber equipped with 5 gloves

- Interior door to separate working environment

- Negative pressure control system

- Linear charging device

- Easy drum loading by saddle opening system

- LPDE Drum sleeve