Synthesis and dispensing in the pharmaceutical industry are certainly important phases where reliability and precision matter, but when high-potent substances are involved, safety matters even more. Furthermore, rigid isolator cleaning and... Read more

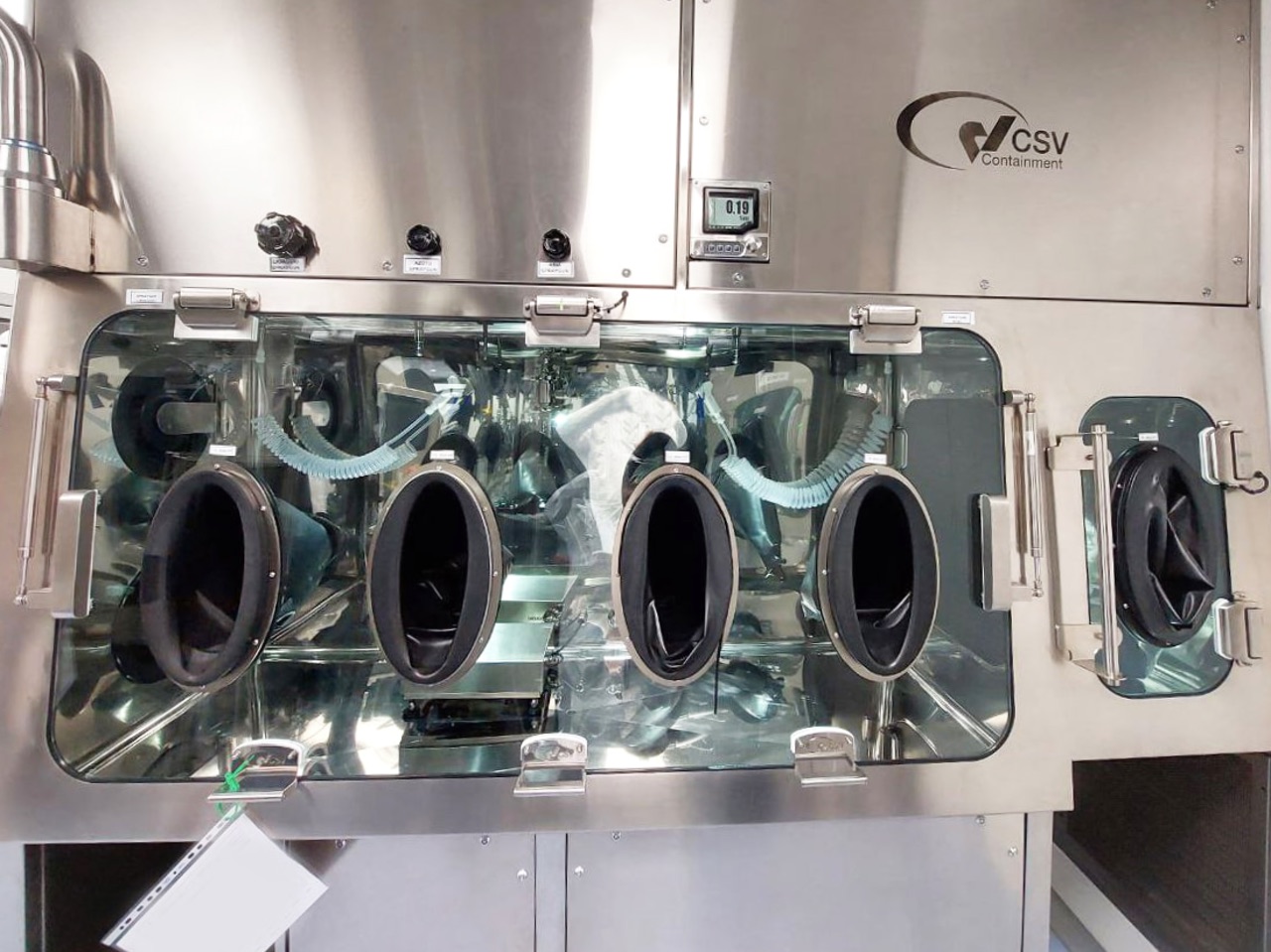

HPAPI Isolator

Synthesis and dispensing in the pharmaceutical industry are certainly important phases where reliability and precision matter, but when high-potent substances are involved, safety matters even more.

Furthermore, rigid isolator cleaning and all the other operations inside these glove boxes require close attention, especially in the HPAPI sector, to ensure not only the safety of operators and products, but also to ensure ease of use and ergonomics. Here is shown a stand-alone ATEX skid for preparation and pumping of washing, which enables convenient CIP operations.

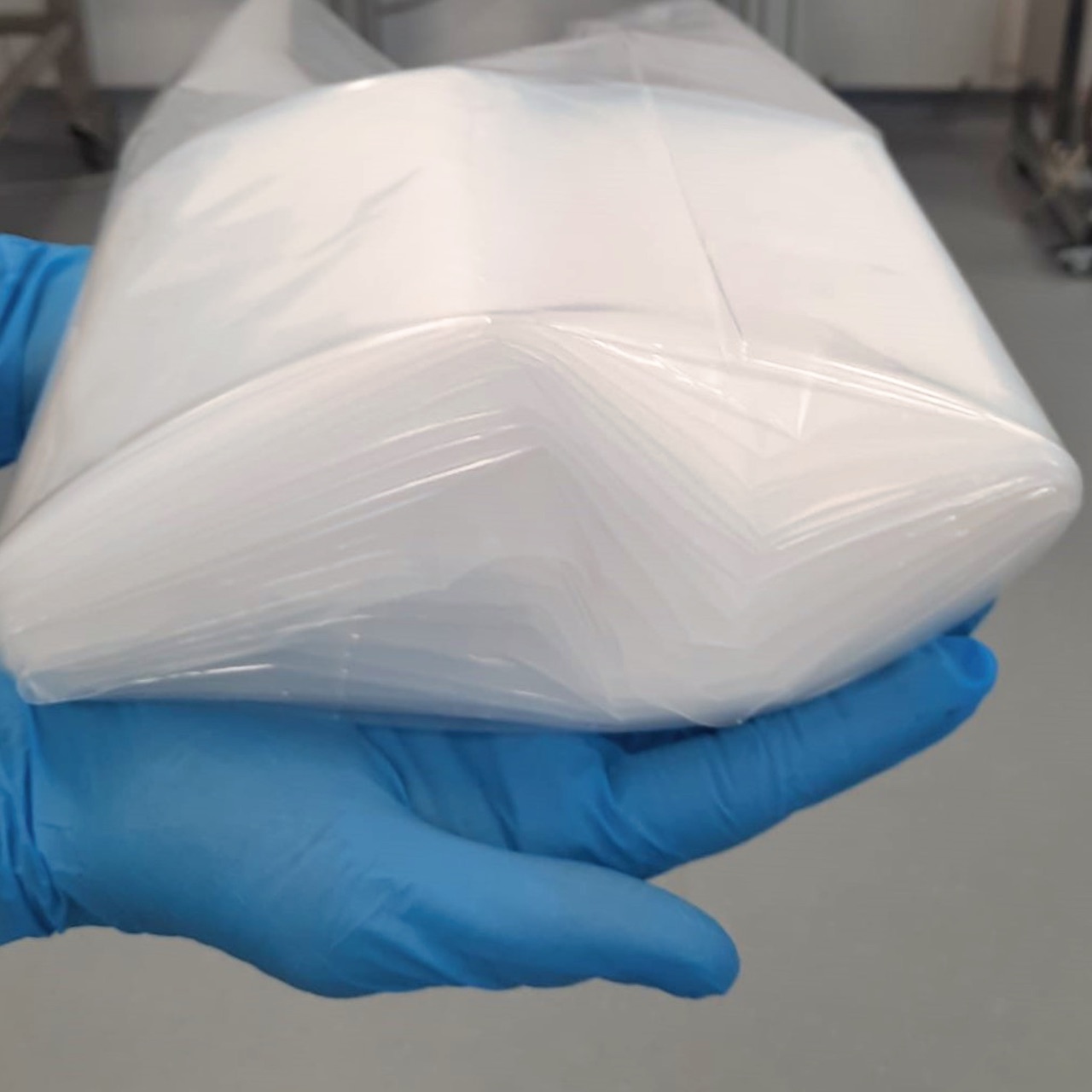

CSV Containment ensures the testing phases, from leakage tests to SMEPACs, as well as validation, thanks to the qualified team of CSV Life Science Group. For the isolator construction, CSV Containment uses the Group’s two workshops in Italy, to serve the needs of Pharma customers. Accessory elements, such as the continuous liners, are also produced in-house, and are dedicated to the bag-out of the machines.

The main featiures of the dispensing Isolator are:

- ATEX pre-chamber and dispensing chamber with EPDM gloves.

- HEPA “push-push safe change system” class H14 filters in supply and exhaust

- O2 monitoring in the dispensing chamber and external isolator with Endress+Hauser sensors

- IP 65 internal isolator – CFR 21 Part 11 compliant – Full GMP standards

- OEB6 band certified with SMEPAC monitoring

- WIP system with spray ball and spray gun for each chamber

- Process contact parts in AISI 316L, frame and non-contact parts in AISI304

- Two DN 300 Continuous liners in the dispensing chamber with 150 mm canister in AISI 316 and dedicated inner door

- TP 1200 HMI panel for equipment monitoring

- Recipes programmable and recallable from the panel

- Data acquisition and the possibility to interface the system with the company BMS

- Vacuum Dryer ATEX – 50 lt

- Two Mettler-Toledo scales with display and printer

A similar synthesis isolator for an HPAPI laboratory typically consists of inlet, synthesis, drying, and outlet chambers.

Typical features for a synthesis isolator can include:

- All chambers are equipped with Jugitec conductive EPDM gloves.

- All seals and gaskets are made of conductive EPDM.

- IP 65 internal isolator – CFR 21 Part 11 compliant – full GMP standards.

- OEB6 band certified with SMEPAC monitoring.

- Process contact parts in AISI 316L, frame and non-contact parts in AISI304.

- Internal surface of synthesis chamber coated with anti-acid treatment.

- HEPA “push-push safe change system” class H14 filters in supply and exhaust

- O2 monitoring in each chamber and external isolator by Endress+Hauser sensors

- Chambers equipped with spray-gun with PTFE hose and spray-ball

- TP 1200 HMI panel for equipment monitoring

- Recipes programmable and recallable from the panel

- Data acquisition and the possibility to interface the system with the company BMS

- Isolator equipped with one DN 300 Continuous liner in the synthesis chamber and one in the exit chamber. The liners are supported by an AISI 316 canister for material exit and access to liners from inside via dedicated doors

- Mettler-Toledo scale on display and printer