Simple, Quick, & Low Cost. The patented Twin Tie® system offers a major advantage over other systems by removing the need to twist the liner before crimping.The twin tie device is... Read more

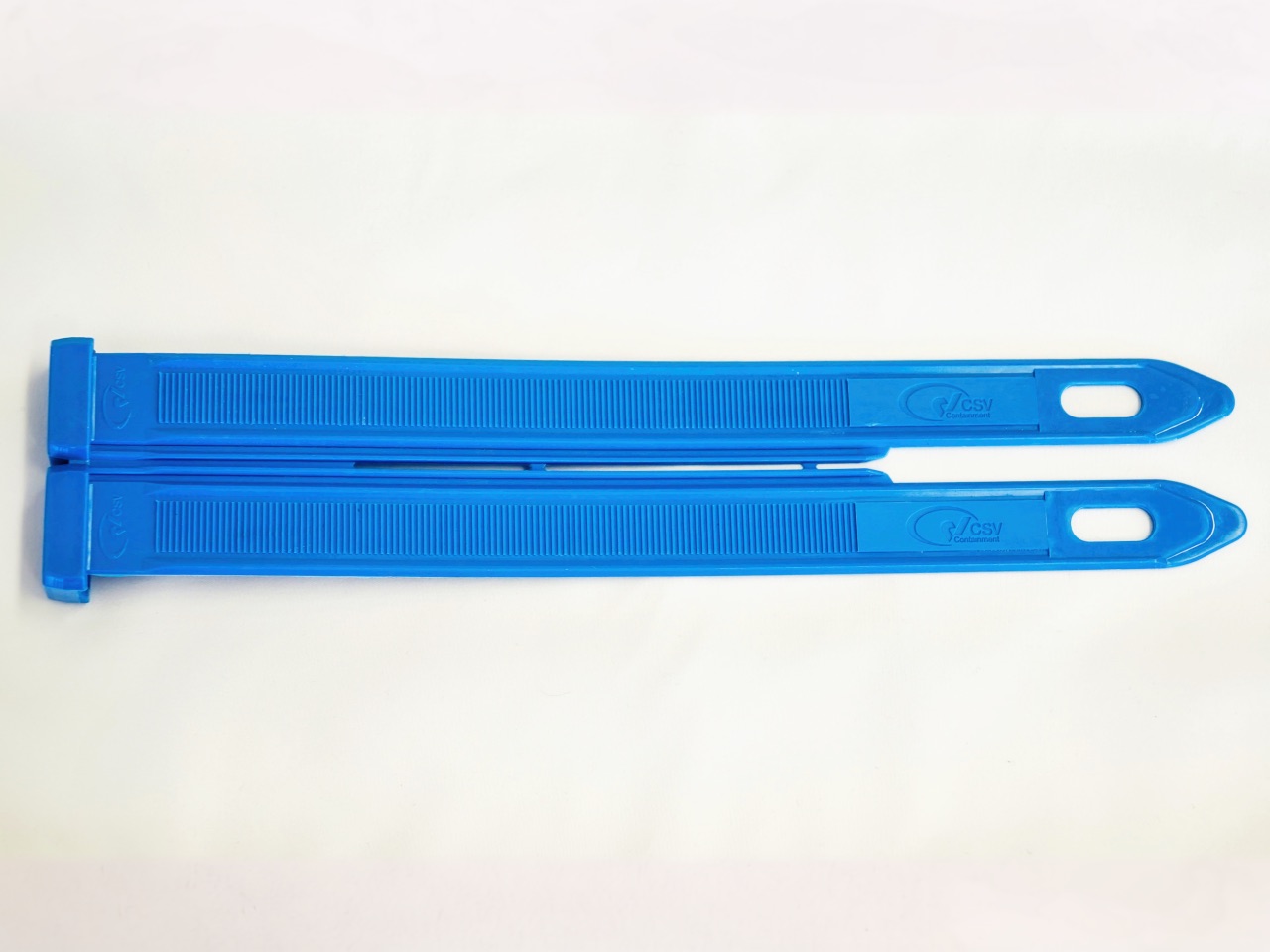

Twin Tie Crimp & Cut Kit

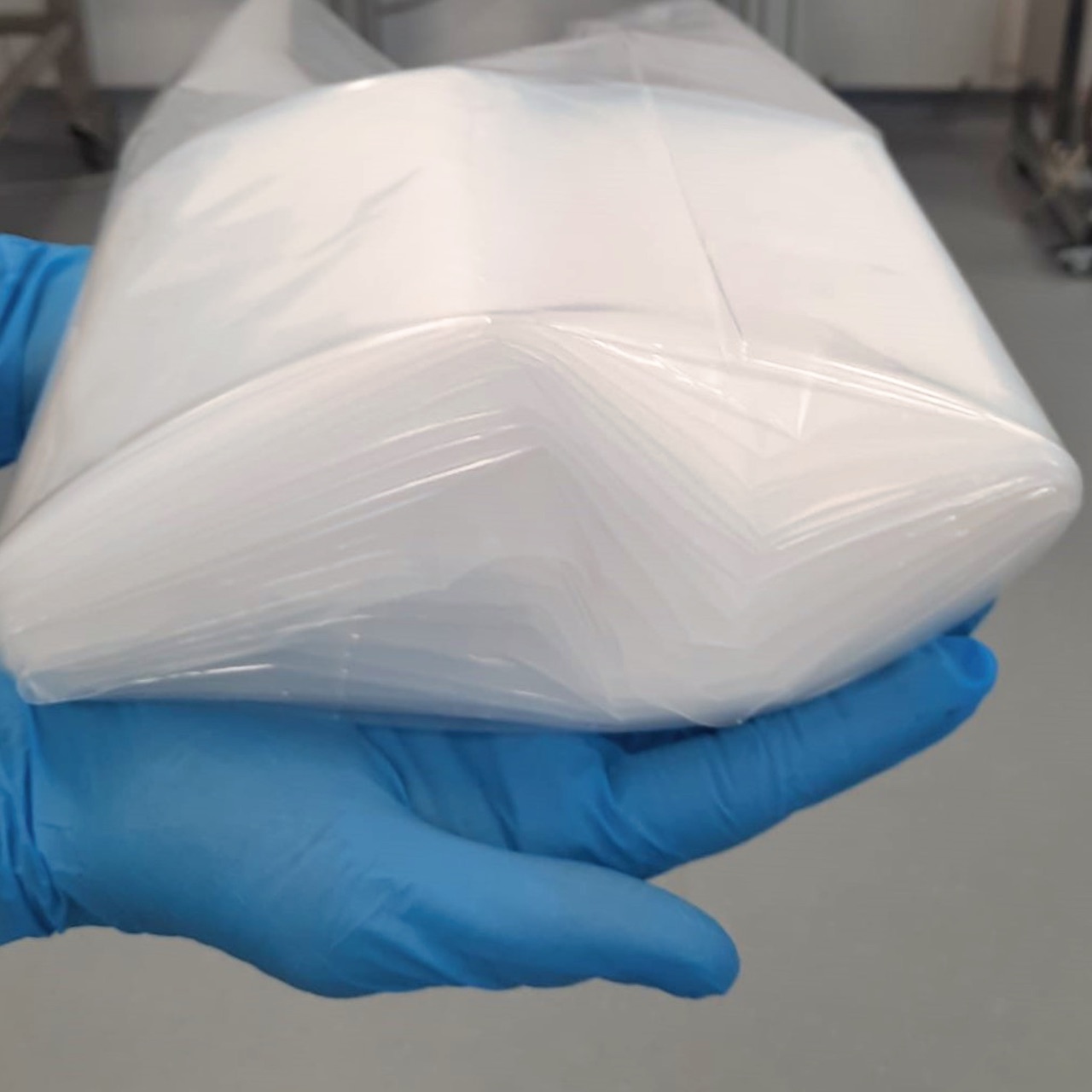

Simple, Quick, & Low Cost. The patented Twin Tie® system offers a major advantage over other systems by removing the need to twist the liner before crimping.

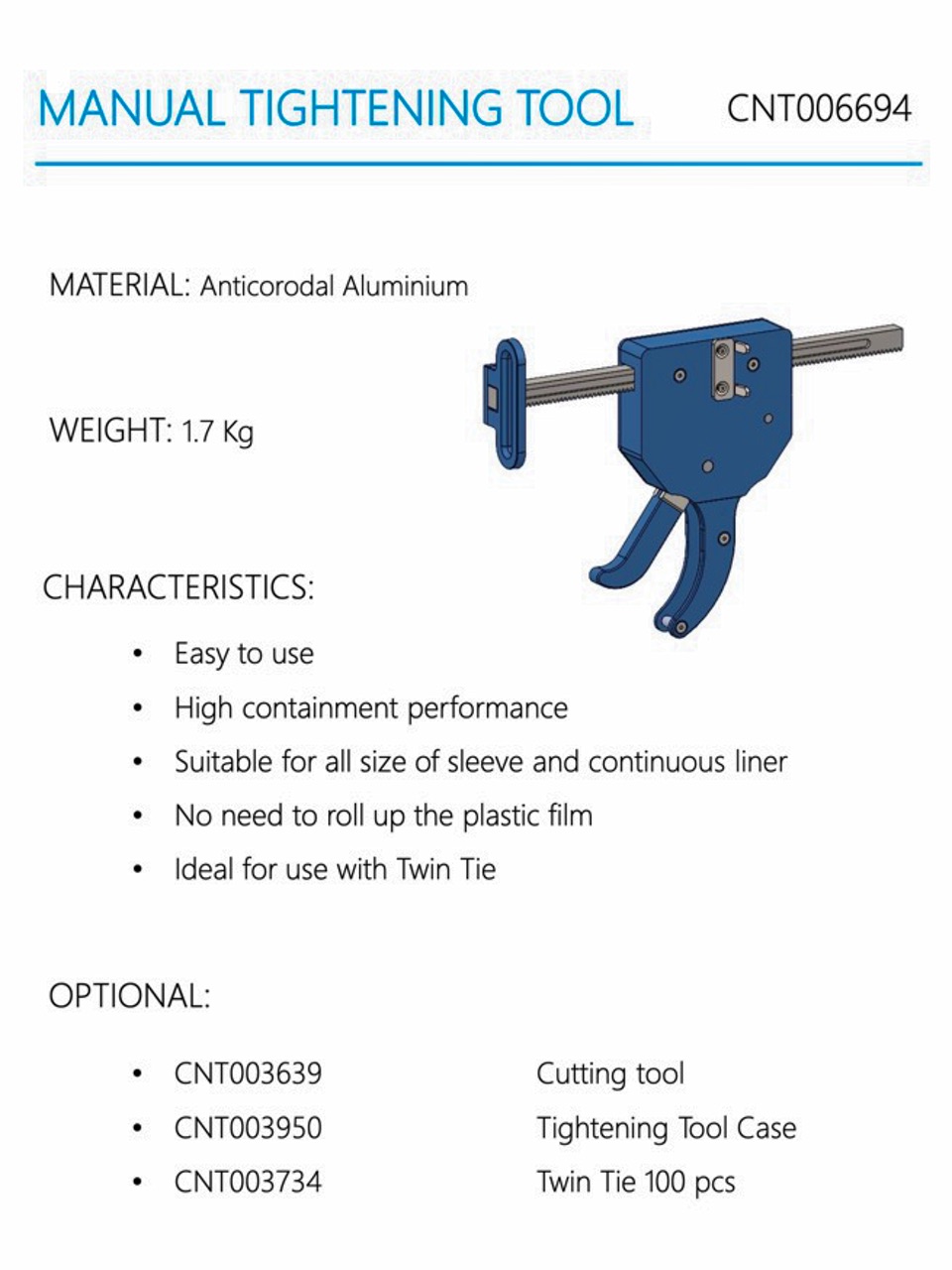

The twin tie device is a dual wire-tie with a solid material section between them that is cut after the wire-ties are pulled tight. We offer both a manual and powered closure tools, however, the manual is so easy to use nearly all clients prefer it.

Once the Twin Tie is tight around the liner, you just cut the solid section between them using the included cutting tool. Once cut the two halves are essentially solid material and offer close to total containment.

The Twin Tie® closure system guarantees a containment level of up to OEB 5 (according to Standard Operating Procedure).

To allow for neater and safer work, the Twin Tie® is sold in a handy case so it is always ready to use. The hand tool can also be easily hung inside an isolator, and the generous size of the clamps allows them to work even with the gloves of a rigid isolator. Dedicated tensioners inside the glove boxes have no surface treatments, so they are not affected by solvents.

The Twin Tie® is pulled manually over the liner before being compressed with the tool, either manual or pneumatic.

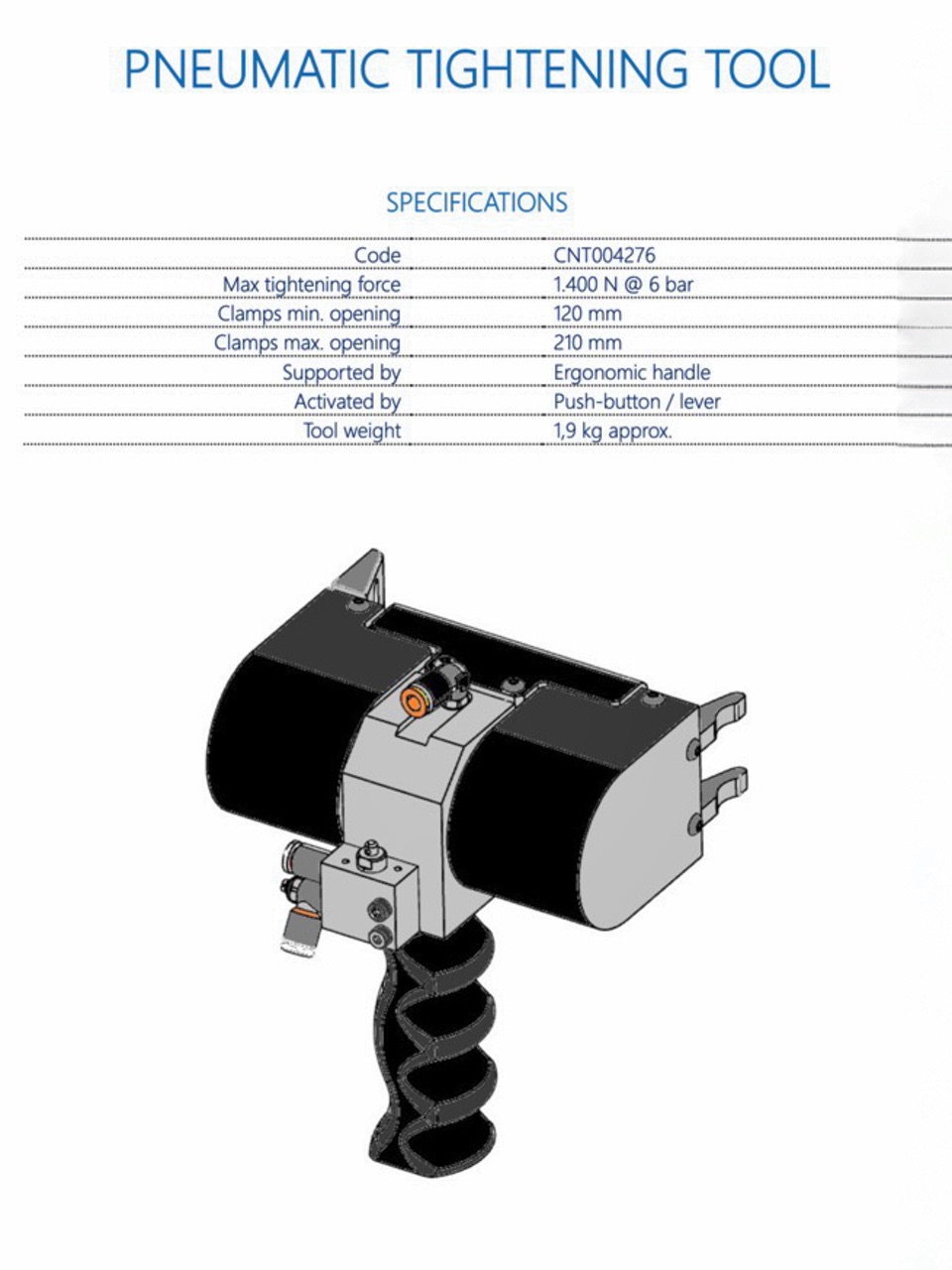

It is then separated using the cutting tool. This very simple and quick operation does not depend on the size and thickness of the plastic sheet. The pneumatic tie puller provides further time savings for those who need to do a lot of crimping. Twin Tie® is also a suitable option for those who need to make separations in series and who need a compressed air connection of not less than 6 bars. The optimal is 8 bars, which can be reached for those who do not have that pressure with an easily connected, small-sized multiplier.