CSV's flexible containment isolators, commonly known as glove bags, provide a safe and efficient solution for high-containment pharmaceutical and bio-pharmaceutical processing. Designed for stringent industry requirements, these isolators are flexible,... Read more

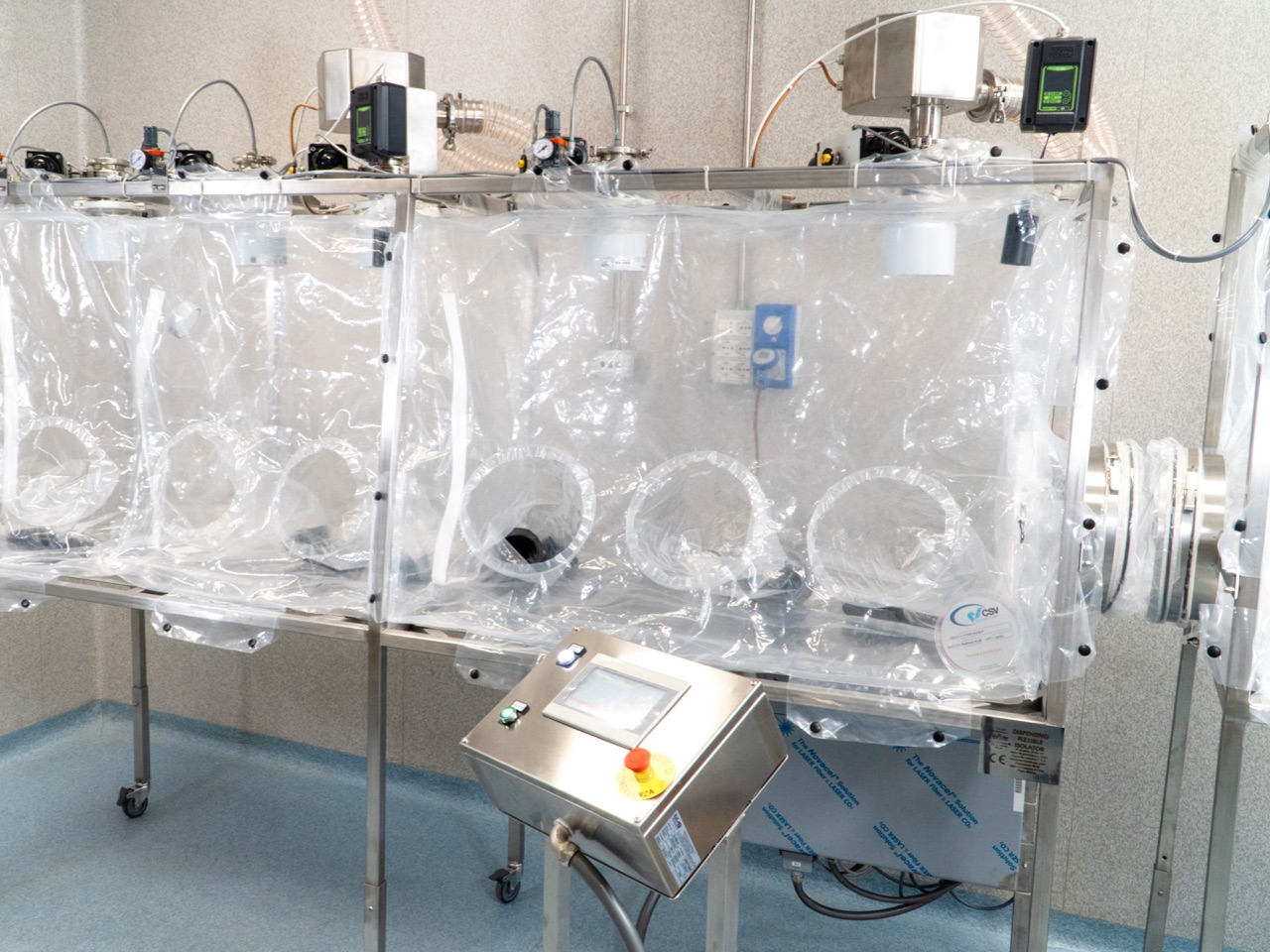

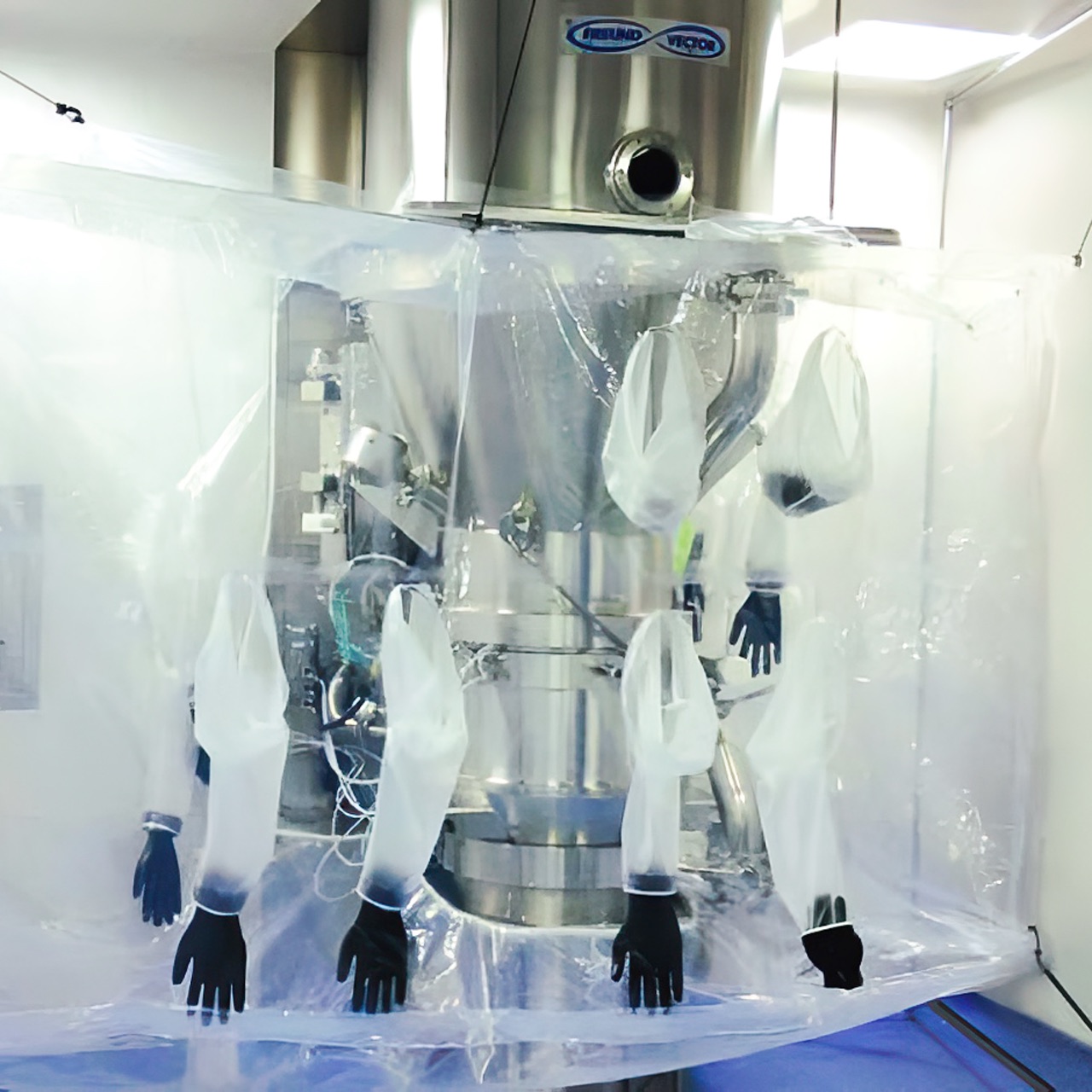

Flexible HPAPI System

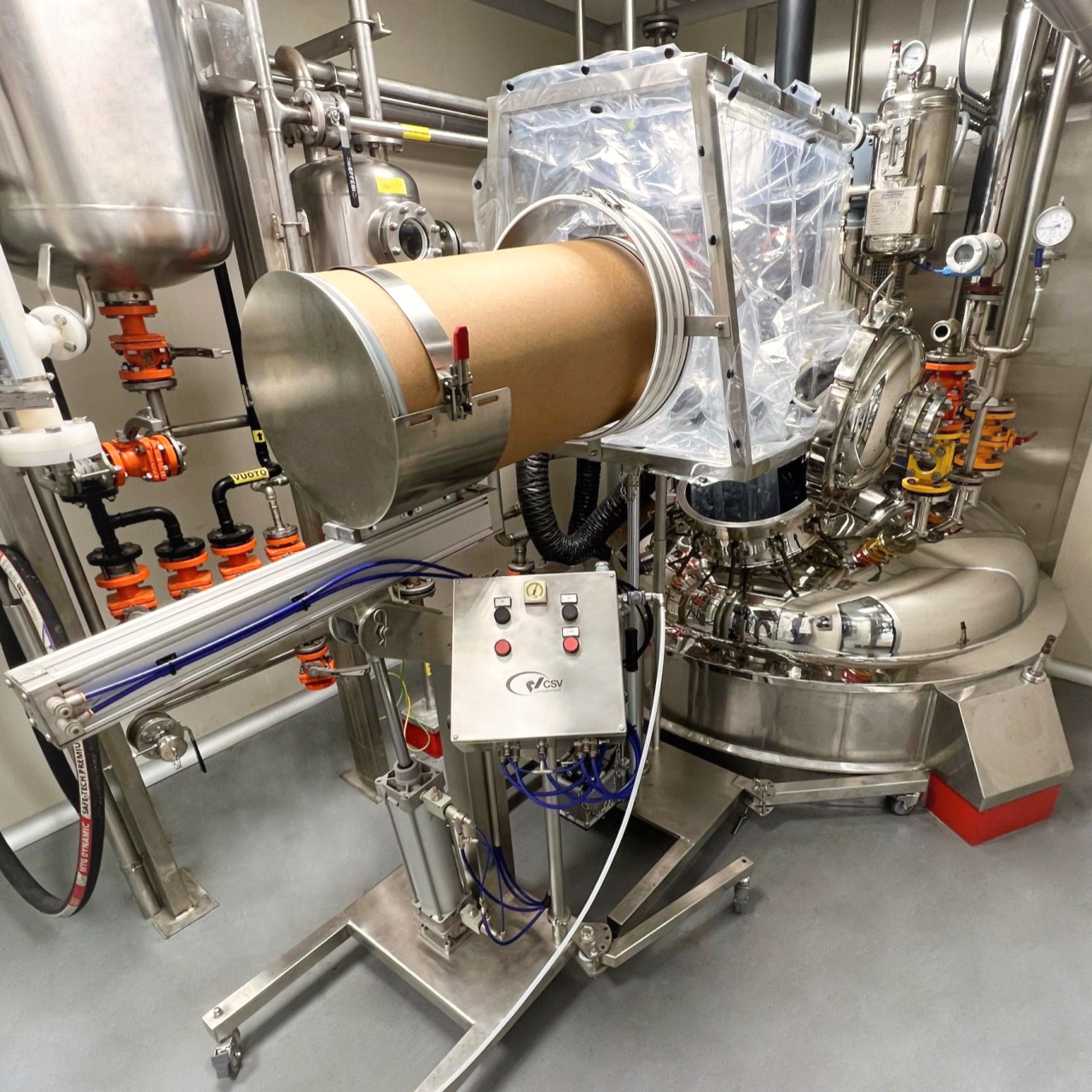

CSV's flexible containment isolators, commonly known as glove bags, provide a safe and efficient solution for high-containment pharmaceutical and bio-pharmaceutical processing. Designed for stringent industry requirements, these isolators are flexible, disposable, and cost-effective. Engineered for safety, efficiency, and ergonomic handling, they ensure reliable containment. Our isolators offer quick delivery, comply with FDA standards, and align with cGMP regulations.

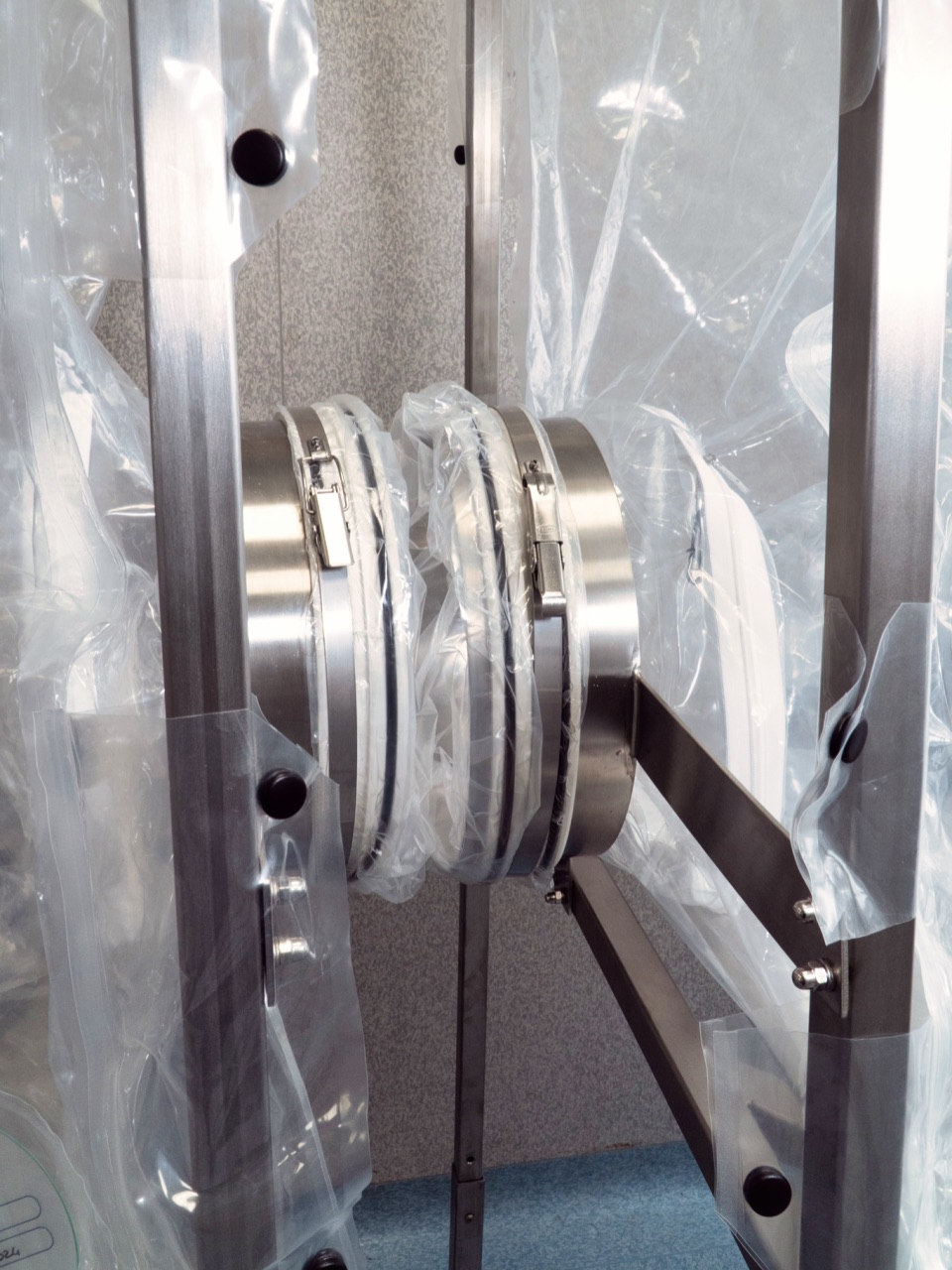

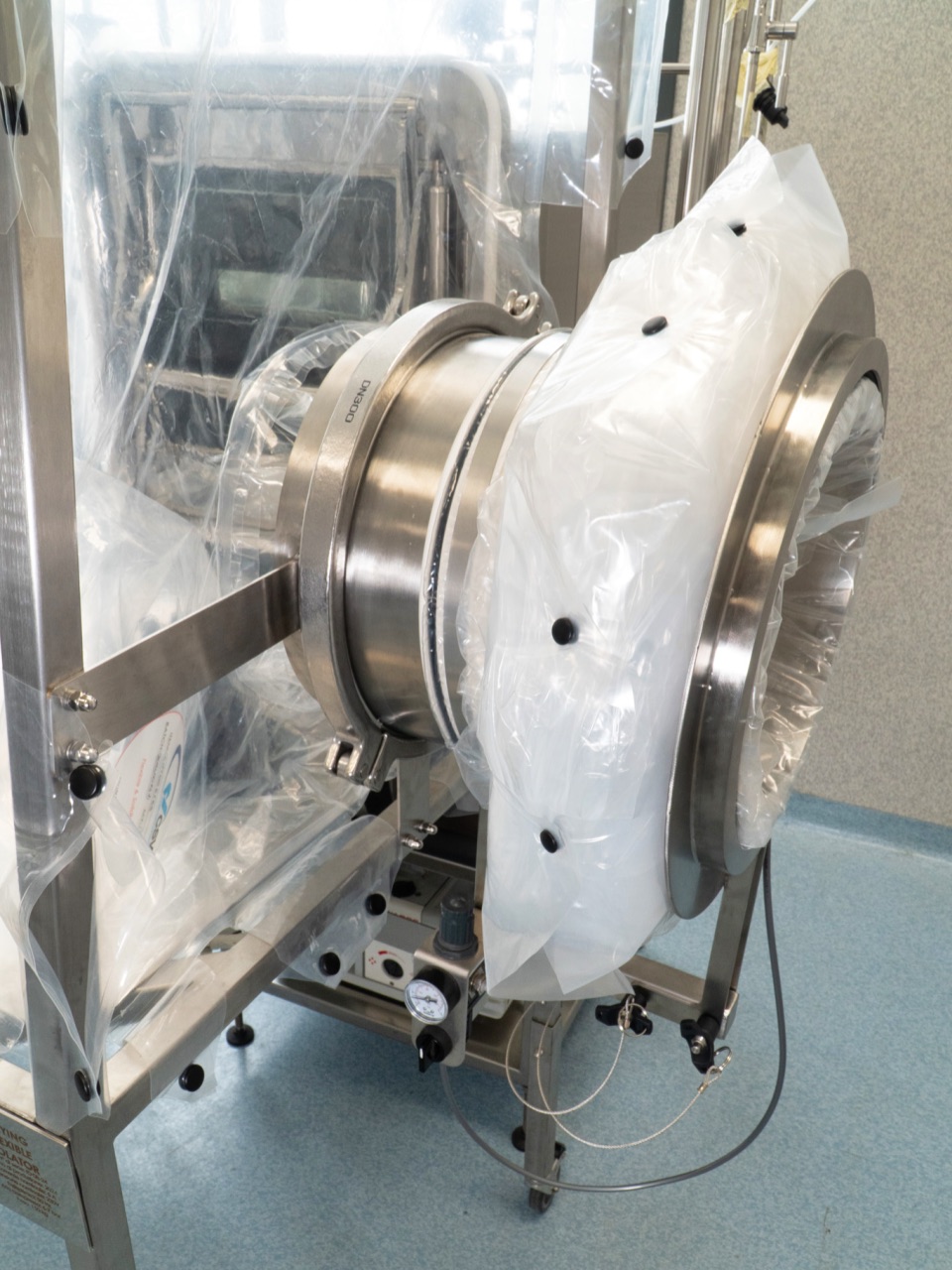

Raw materials are introduced from the pre-chamber, which is equipped with a zipper door. Passage to the dispensing chamber is always via a zipper door. The connection between the individual isolators is provided by a series of sleeves equipped with zippers. All glove bags are equipped with a sufficient number of gloves suitable for ensuring that all operations are carried out comfortably.

In this particular system, during the inerting stages, data on the minimum amount of oxygen in the chambers are transmitted to the control panel from the oxygen detectors. Each chamber is equipped with an internal detector. Air extraction fans are placed overhead and connected directly to the existing on-site system. An HMI interface conveniently provides operators with control of all cycles.

The same solution, using rigid isolators, would have involved a significantly higher expenditure of energy and economic resources. The isolators mounted on each of these structures are easily removable and are usually dedicated to campaign. In order to conveniently reconnect all equipment, solutions such as the convenient grommets made by CSV Containment, again made of flexible material, have been provided, combining convenience of use and safety.