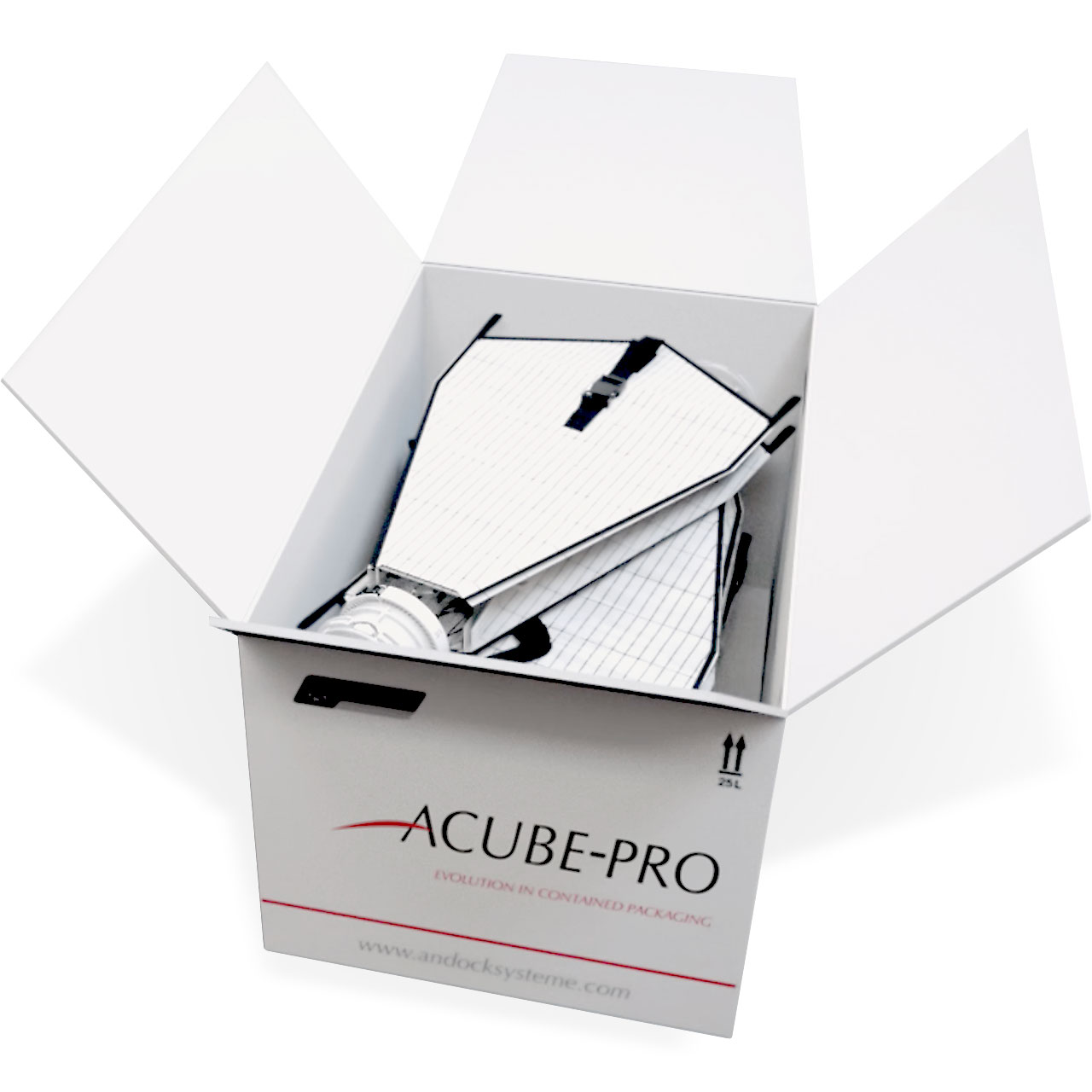

ACUBE PRO is an integrated, single-use containment system composed of two independent liner systems. The inner liner acts as product bag to protect the product from environmental impacts and vice... Read more

Single-use FIBC Containment System for Bin Blending

ACUBE PRO is an integrated, single-use containment system composed of two independent liner systems. The inner liner acts as product bag to protect the

product from environmental impacts and vice versa. The outer liner is a reinforced protective layer that can withstand mechanical stress. The dual

liner construction allows the ACUBE PRO to be used for highly contained, single use, bin blending.

The ACUBE PRO Bin Blending Frame (sold separately) can be customized to fit your specific bin blender and aids in both handling and blending operations. The frame's stabilizing plates add rigidity to the system which ensures optimal blending performance and easy and complete emptying of units containing poor flowing products.

Equipped with the new AVAX single use containment valve and a disposable ACLAMP flange fastener, the ACUBE PRO flexible containment system allows material handling and blending operations under fully contained conditions. ACUBE PRO is available in various sizes and can be utilized in all types of powder, granule or tablet handling.

ACUBE PRO Features:

- All-in-one FIBC handling and blending system

- Fully integrated high containment system

- Flexible but robust multi-liner construction

- Easy emptying of poor flowing products

- Can be customized for existing bin blenders

- Suited to pressure and vacuum applications

Benefits of Single-Use, Flexible Containment Systems:

- Eliminate cleaning (time, cost, energy, downtime, complexity)

- Eliminate cross-contamination risks

- Improve operator safety handling potent ingredients

- Improve process and manufacturing flexibility

- Improve lead times, as well as start-up, turn-around and change-over times

- Ready to use right out of the box (even pre-sterilized)

- Easily integrated into existing stainless steel systems

- Reduced need for capital expenditure

- Reduced warehouse footprint

- Reduced environmental impact